Dinghy Repair Introduction

Go To: Sailing - Dinghy Repair

Posted on 19 February 2008 18:23

How fun do you think it would be to restore a used dinghy back to better condition? Find out with us on our dinghy restoration project.

Chances are, your first dinghy may not be a brand new one with all it's pearly white shininess. Excellent bargains can be gotten on second hand dinghies, which could be anything from a couple of years old to 40 years old. When dinghies are built, they're built to last, and the good thing is, if they're taken care of, they hold their value much better than a car of similar age.

Unfortunately, not everyone buys into the whole "looking after things" idea. Also, accidents can be pretty common in this sport, and while sailing doesn't have a high fatality rate for sailors, the same cannot be said of boats. Split wood, crunched fibreglass, ripped sails, bent masts - these are all entirely possible, and depending on the severity, all entirely fixable.

Of course, the damage on a boat can easily be too much to make it worth trying to fix it. If there is severe structural damage, such as a badly damaged hull or destroyed mast step, get an expert opinion on whether or not it's worth fixing. If you're just starting out on boat repairs however, small jobs can be much easier than they look at first. Small filler jobs, repainting or repairing sails are all easily within the skillset of the novice sailor.

If you don't know what you're looking at, you should try to take along someone who does know when you're looking to buy a boat - to the untrained eye, a damaged boat may be either more difficult to repair than it actually is and you've set yourself up for a fall, or a lot easier to repair and you miss a bargain. By the end of this series on boat repair, hopefully you'll be more clued up on what to look for.

At Caution Water, we like to lead by example. So, we just bought a brand new old Laser 2 for £500. The boat in question is an ex-University boat, 4th or 5th owner by now, 27 years old according to the sail number, so has obviously seen a lot of use in its days.

Photo 1. The boat

Photo 2. The boat (again)

Photo 3. The Cover

There is a lot of working that needs doing on the boat - but none of it really major. There is a small hole in the hull which needs repairing, lots of minor cracks and crazing in the deck gelcoat that need filling, a few fixtures that need replacing, and some other minor work.

In this first article in our series will show you all the damage on our boat and spars that needs repairing, (sails will come later), and we'll give a brief run down on what we're going to do to fix it all up.

Deck

The deck has surface crazing and discoloration in a number of places. There are also some larger cracks (although not deep). We plan to repair these with gelcote filler.

Photo 4. Deck crazing

Photo 5. Deck Damage

Some deck fittings, such as the halyard plates, have been screwed onto the deck too tightly, which has cracked the deck. Structurally they are sound (the strength is from below), but we need to put some small plates on top of the deck to stop the deck damaging further.

Photo 6. Halyard Plates

Photo 7. Impact Damage

There are a few small impacts or chips in the fibreglass surface, which we plan to fill. There are also a number of grazes and chips along the edge of the gunwhales which we plan to sand and fill.

Photo 8. Deck Chip

Photo 9. Gunwhale Damage

On the back of the boat, a previous owner has decided to fill in the patch where the rudder sits so the rudder no longer sits properly. This will need to be sanded down. Also, some shoddy repairs to the back corners needs to be looked at.

Photo 10. Rudder

Photo 11. Corner Damage

The inside of the cockpit has quite a few small surface cracks, which again need filling.

Photo 12. Foredeck damage

The front of the foredeck, the very front of the boat has the worst piece of deck damage, where there are a few minor cracks, and the edge of the gunwhale on the bow has been abraded off or chipped away. This needs to be filled.

Mast and Boom

The boom has had some fittings on previously which were removed by force leaving the rivets behind, which we plan to remove. We plan to replace the outhaul system, and generally clean up the boom, using some metal polish to return its' former sparkle.

Photo 13. Boom Fittings

Photo 14. Clean the Mast

The mast is in decent condition, although some of the rollers inside the mast could do with replacing - we haven't decided yet on whether to do this. The general condition of the rest of the mast is fine, and just needs polishing up.

Photo 15. Clean the Mast

Photo 16. Mast Rollers

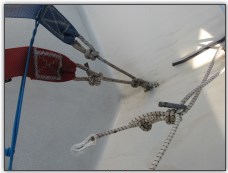

We also plan to replace the trapeze wires - they haven't been used for some time and the steel wire has become twisted. This shouldn't be too difficult a job, since they are bolted to the mast instead of riveted.

Photo 17. Trapeze Wires

Hull

The hull has had a few repair jobs before - the bow and both corners on the back have had previous repairs, and need some attention to stop them showing so clearly. These will be sanded before being repainted.

Photo 18. Old Hull Repairs

Photo 19. Old Hull Repair

An old hull repair on the side has not been completely sanded flush, and we have the hole on the front to repair. It is a hole through to the bouyancy tank, which in an ideal world we would cut an inspection panel in the deck, and repair it from inside. However, we've taken advice of several people, and agreed that cutting the inspection panel to repair the hole properly would weaken the boat more than doing a simple filler job on the hole instead. Since the hole is so small (less than an inch in length) and isn't in a structural area, a filler job should hold for a few years to come.

Photo 20. Hole in the Hull

Before the hull is repaired however, we need to sand the entire hull lightly. Once the repairs are complete, we plan to repaint the entire hull. We considered replacing the gelcote, however for the age of the boat and the amount of time it would take, we decided painting was the better option.

Foils

The rudder is in more or less perfect condition, and only the raising rope on it needs replacing. The centreboard however has a couple of large chips taken out of it, and we hope to fix this, although we're not quite sure how yet!

Photo 21. Centreboard Chips

Photo 22. Shock Cords

Also, the securing rope and shock cord on the centreboard needs evaluating and replacing.

Standing Rigging

This is more or less OK - the halyards are fine, although some metal plates need to be fixed between the fixing point and the deck, to stop more damage occuring to the deck. The forestay needs replacing, since the wire strands are starting to break, although this is a more difficult job to do since the wire is riveted onto the mast.

Running Rigging and Ropes

Much of the rope on the boat needs replacing. The main and jib halyard ropes are gnarly, dirty and old, and we hope to resplice new rope onto the halyard wires rather than replacing the entire assemblies.

Photo 23. Halyards

The mainsheet is of good condition, although most other ropes, including the outhaul, non-existant downhaul and kicking strap are going to be replaced. We plan to replace the jib sheets because while they're good condition, they're the same colour as the mainsheet, so we will change them to avoid confusion. We plan to add pulley blocks where necessary, and hopefully we can use all the current deck fittings.

We also need to add in running rigging for the spinnaker, which hasn't been on the boat before, so therefore isn't setup.

Photo 24. Toestraps

Photo 25. Cockpit Shock Cords

Inside the cockpit, we plan to replace all the toestraps and shock cord systems for them.

Trailer

The trailer isn't in perfect condition - in fact, the mast supporting arm lasted for about 15 of the 20 mile journey home, then fell off! However, the trailer itself is in decent condition - we plan to get it professionally serviced, and see what they say about the state of it.

Summary

So - that's it! Our project for the next few weeks/months now stretches out in front of us. We'll take it a step at a time, and everything we do will be documented for you to see and follow along if you have a boat in similar condition. We're not saying we're going to do it the perfect way, and you'd undoubtedly get a better job by taking it to a professional boat chandlery, but at a cost of several hundred pounds more than what it's going to cost us.

We are also open to criticism or suggestions - so if you think we're going about something the wrong way and can tell us better - by all means get in contact and let us know.