Centreboard Project - Shortening

Go To: Sailing - Dinghy Repair

Posted on 27 April 2008 17:51

If your lake is quite shallow, you may look at ways to make it easier to sail, such as shortening your centreboard. You should think twice before doing this - it is a particular size to counter the forces against your sail, and shortening it can upset this balance.

This is our first guest article, which comes from our friend Tony, who sails a Mirror. Tony, a magician, is going to show us how to make some of your centreboard disappear, if your lake is quite shallow. Take it away Tony! - Becky and Richard

Our lake is very shallow in places and a full length centre board hits the bottom in places (although my crew claims this comes in handy at times as he uses it as a "handbrake" to stop me shooting into the dinghy park when I am coming in too fast). My friends at CautionWater found me this old centreboard somewhere in the depths of the Bosun's store (see Photo 1).

Make sure you have somewhere clean, clear and safe to work. These portable workbenches can be found for £10 in most DIY stores and really are an extra pair of hands (see Photo 2).

Photo 1. The initial centreboard

Photo 2. A toolbench

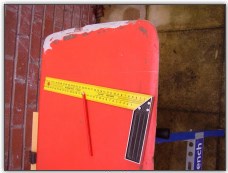

The old centreboard was obviously well used and had been repair a number of times (see Photo 3).

Photo 3. Measuring the new size

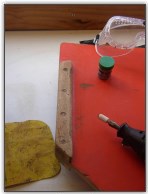

Photo 4. Using a square

Photo 5. Using the saw instead

I used a square to mark a straight and level cut (Photo 4). If you haven't got a square, the handles of most modern plastic saws are made in such a way as to work as either a 90º or 45º square (Photo 5). I used my other centre board as a pattern to mark the curve on the bottom of the blade (Photo 6). If you haven't got another centreboard as a pattern, you can use anything circular as a pattern like this roll of sticky tape, a can of paint, a big coffee mug etc (Photo 7).

All marked up and ready to start cutting, I used an electric jigsaw as it allowed me to shape the corners. You could always use a handsaw and then shape the corners afterwards. Note how I have set up my workspace so that I will be cutting away from the power lead (Photo 8).

Photo 6. Marking the shape

Photo 7. Marking the shape

Photo 8. Ready to cut

Next I used a plane to shape the edges of the cut. I could have used a power plane or a big sander but you have more control with a small hand plane. You can follow the laminations in the plywood to ensure that you have a neat, even shape (Photo 9).

Photo 9. Cleaning the end

Photo 10. Sanding down

The final stage before painting, I sanded the centreboard down to remove any loose and flaking paint, to get the edges neat and to give a good key for the paint (Photo 10).

For no other reason than I thought that it would look good, I used some polishing paste and my multi tool to shine up the brass screws on the handle (see Photo 11). (Oops I almost forgot to say it but make sure that to ALWAYS wear safety glasses when using power tools).

If your not lucky enough to have a workshop (shed) like me and you are using your Mum's/Wife's kitchen, make sure that you put plenty of paper down to protect your work surfaces before starting to paint.

Make sure that you read all the instructions on the varnish and paint and stir well before use. If I had read the instructions on this International Yacht Varnish I would have known that it said "not for Marine Use" - where do they expect people to use yachts?????

Photo 11. Polishing the screws

Photo 12. Ready to Varnish

I masked of the main part of the board before using the varnish because I wanted the primer to penetrate the board, which would be prevented by any varnish overspill.

Photo 13. Mixing the varnish

Photo 14. Varnishing the wood

Now the boring bits. Firstly I used a couple of thinned coats of primer to get a good penetration into the wood, a final primer coat, two undercoats and finally three top coats to get a good finish. I applied the paint sparingly and allowed it to dry thoroughly and gave it a light sanding (240 grit paper) between coats (see Photo 15).

Photo 15. Primer and Paint

Photo 16. The finished shortened board

The finished article, but it makes my normal centreboard look a bit tatty which now mean another job for another day. I don't know why those penguins are turning their noses (beaks?) up at my handiwork (see Photo 16).

Don't forget to work in a clean, tidy, safe workspace and read the instructions on any power tools and paints etc and always wear eye protectors when using power tools.

- Tony