Dinghy Repair Toestraps

Go To: Sailing - Dinghy Repair

Posted on 27 August 2008 18:22

Toestraps are an essential part of a hiking dinghy - without them, hike too far and you'll go for a swim! The toestraps in our Laser 2 were adequate, but we wanted to completely overhaul the boat, and felt they needed retensioning and adjusting to our needs.

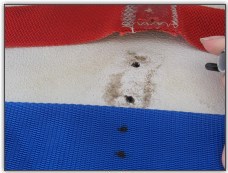

As you can see in the old photos, they're pretty dirty and have seen better days (Photos 1, 2 and 4), and we stood no chance of retensioning the rope that was currently on them, so we decided to replace them.

Photo 1, The old toestraps to be removed

Photo 2, The old toestraps to be removed

Photo 3, Removing the toestraps

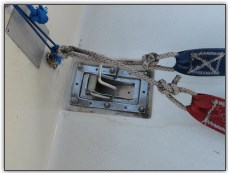

We got the webbing off the internet, from Baseline Marine, which cost about £4 for the 3 metres we needed. The first job was to remove the toestraps, so the rope got sliced off, the metal securing the toestraps to the middle of the cockpit unscrewed, and the toestraps removed (Photos 3 and 4).

Photo 4, The old toestraps to be removed

Photo 5, Undoing the toestrap fittings

Becky's mom's skills with the sewing machine were once again put to the test. We measured up the webbing using the old webbing as a template, and then set about sewing the ends over much like they were before (see Photo 6). The webbing was fairly easy to sew (not like the sail window this time), so first a box was put around the area to secure (see Photo 7), and then diagonals sewn across to secure it properly (see Photo 8). Both ends were done the same.

Photo 6, Measuring up against the old

Photo 7, Sowing the ends

Photo 8, Making the loop secure enough

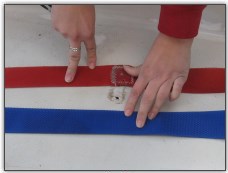

Photo 9, Measuring the fitting point

Next came determining where the centre was, to mark it for holes and to put a reinforcing patch on. First of all, we hooked the new toestrap up into the position it would eventually be in, with some rope to hold it in place (see Photos 10 and 11). When that was tweaked into the correct position, we marked approximately where the holes needed to be. Next, we took a small (inch and a half long) piece of webbing and sewed that over the area where the holes would be, as in Photos 12 and 13 (the other side to the side we had marked with the pen, obviously). We then repeated this entire process for the other toestrap.

Photo 10, Setting the new toestraps in place to check sizing

Photo 11, Setting the new toestraps to adjust the fitting point

Photo 12, Marking the fitting point

Photo 13, Adding reinforcement around the fitting point

To fit the toestraps, first we had to clear all of the old silicon sealant from around the screw holes. You should use silicon sealant around any screw fitting that goes into the boat, to stop water getting into the tanks, or into the fibreglass. Unfortunately it's rather awkward to clean off once it's on, but a sharp screwdriver makes a simple job of it (Photo 14). You don't have to get all of it off, just get it cleaned up to the point where there aren't any large lumps or loose bits. (Photo 15).

Photo 14, Clean all the old silicon sealant off

Photo 15, Nice and clean!

At this point we'll note that we did do a dry run fitting first, to make sure they were positioned right, before we dropped in the sealant. You may find it easier to work the screws through the webbing before you even get near the boat - if theyre sharp screws you may be able to just screw them straight through, if they're not, then you may need to use a sharp pair of scissors and bore a small hole into the webbing. Don't worry about weakening it - this is why we put the small patch over the top, to strengthen it.

When ready, put a patch of silicon sealant over the area where the metal plate will be; don't worry about using too much, you can wipe off the excess later (Photo 16). Better to use too much than to end up with a boat with water in! Place the screw fitting and webbing over the silicon sealant, and then screw it down (Photos 16, 17 and 18). It's best to wipe off any excess sealant that squeezes from around the sides now, rather than let it dry.

Photo 16, Add new sealant around any holes

Photo 17, Position the fitting and start off both screws

We found in our Laser 2 these metal fittings can be quite painful - unfortunately they are located exactly where the crew's knees end up! Because of that, we've ended up putting some thick duck tape lengthwise on the toestrap over the screw fittings, and then taking more duck tape around the toestrap to hold that in place, to protect our knees. We've also bought kneepads which help too.

Photo 18, Finish off both screws, and wipe off excess sealant

Photo 19, New ring added at the front

Next came securing the ends. At the front, we wanted to put in a ring that we could attach more things to, such as a pulley block for the spinnaker halyard, so rather than just tying the rope around the front fitting, we added this ring (Photo 19). We were unsure of the load we could put upon the front fitting, but spinnaker halyards rarely come under the kind of load that a main or jib halyard do; and besides, we won't be using the spinnaker often.

Photo 20, Rig the back of the toestraps

Photo 21, Rig the back of the toestraps

We started rigging the toestraps at the back. Because they are each secured in the middle, the tension for the helm and crew parts of the toestraps are controlled independently, unlike some boats, for example most Enterprises, where one continuous toestrap, not securely anchored in the middle is used (see our Enterprise Rigging Article). At the back of the cockpit was a short length of bungee elastic, which had previously been screwed into the jammer cleat for the mainsheet traveller. This elastic was in good condition, we simply burned the ends to neaten them up, and left it in place.

Photo 22, Rig the back of the toestraps

Photo 23, Rig the back of the toestraps

Using 3mm rope to rig the toestraps, we first passed the working end through the bungee loop (Photo 20), and through the pocket we had sown in the end of the first toestrap (see Photo 21), then back through the loop in the bungee again (see Photo 22). Next, the end of the rope was taken through the metal fairlead just above the self bailer, then back through the bungee loop (Photo 23), and through the strap pocket in the next toestrap (Photo 24), then back through the bungee again (see Photo 25).

Photo 24, Rig the back of the toestraps

Photo 25, Rig the back of the toestraps

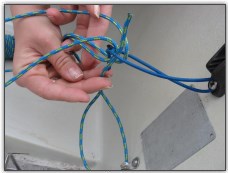

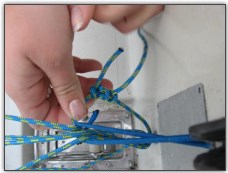

Next... you guessed it! Back through the metal fairlead (Photo 26), and this completes the route for the rope. We tied a reef knot in the rope (Photo 27), and trimmed it off the length of rope we were using. We burned the ends (Photo 28), then put a couple of hitches in the ends of the rope around the reef knot to further secure it in place (Photo 29).

Photo 26, Rig the back of the toestraps

Photo 27, Rig the back of the toestraps

Why did we do it like this? Well first of all, since both toestraps are using the same piece of rope, they can be tensioned in one go, quickly, easily and equally, by simply untying the hitches and reef knot and tightening the rope. The bungee we passed the rope through will help pull it up from the cockpit floor at the back, so to hook our feet under we simply slide a foot to the back of the cockpit, under the toestrap, and move the foot forward. Finally, the rope went through the metal fairlead to make a secure fitting for the toestraps to strain against.

Photo 28, Tidy up the rope ends

Photo 29, Secure the knot

At the front of the cockpit there is a piece of bungee stretching from one side to the other, from small bullseye fairleads located on the top of the inside of the cockpit. This is to raise the toestraps at the front of the cockpit for the crew, in a similar way to the back of the cockpit. The elastic cord has a twist in it, which holds the toestraps in place so they don't slip too much. The toestraps are pulled through in Photo 30, and then they are rigged in exactly the same way as the back toestraps, through the metal ring (Photo 31) instead of the fairlead.

Photo 30, Rig the front of the toestraps

Photo 31, Rig the front of the toestraps

Summary

All boats have their toestraps rigged differently; in a topper for example, small pieces of vinyl plastic are held in place by screws to clamp down on toestraps for the sides and middle of the cockpit. In Enterprises, they may not be screwed down at all but instead tied around pieces of hardware such as the mast step. However, no matter how the toestraps are rigged differently, it's not a difficult job to replace them if they start to fray. There are plenty of places around to get hold of webbing, Baseline Marine do some good deals and varying sizes (about 90p per metre for what we used), or you may even be able to get padded toestraps (particularly for Lasers) which may be good if you are hardcore and sail for hours on end whenever you get the chance! No matter what, don't be too intimidated about replacing them, all you need is someone who can sew, and a bit of common sense (and this article) to rig them back later!

Always remember, if you're taking something apart on your boat and you're not really familiar with it, take plenty of pictures that you can use to put it back together again later!